We developed two AI Models, one for extracting topics with from the ideas and classifying them into categories, another for finding related ideas within each cluster

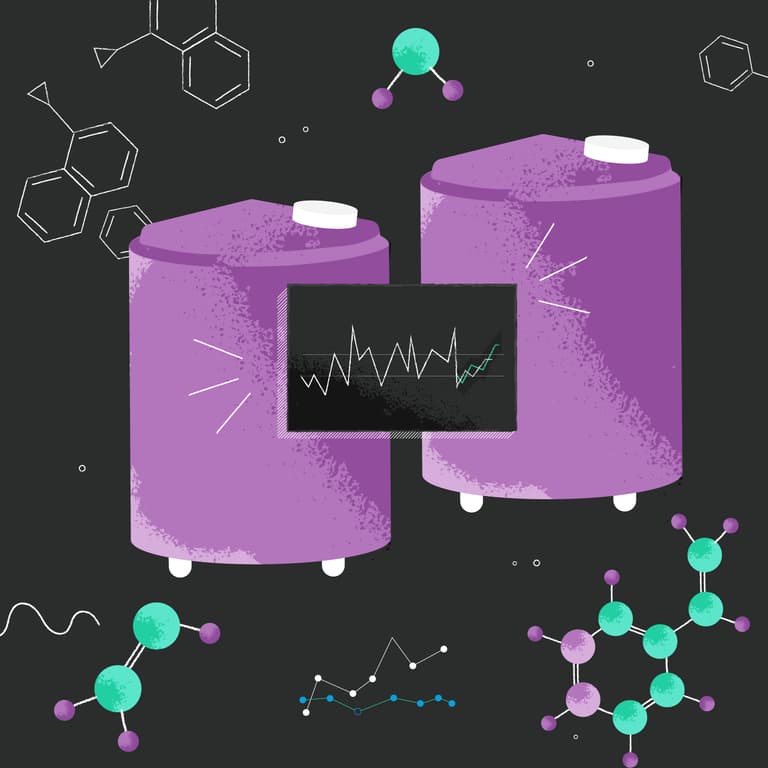

Predictive AI Model For Pharmaceutical Company

Client Location

Krakow,

Poland

Tech Stack

Python, Tensorflow,

Google Cloud Services

Team

2 Data Science Engineers

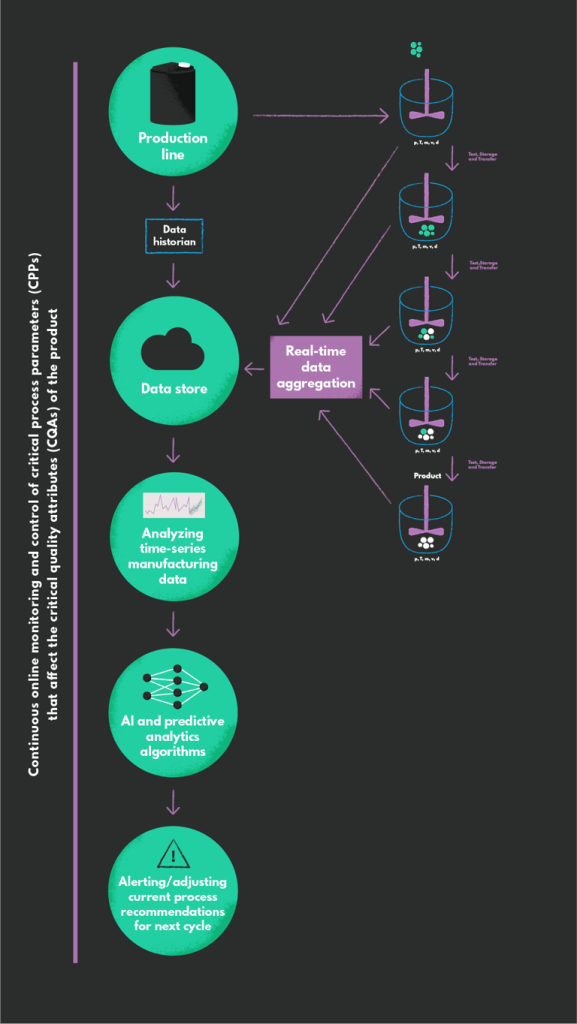

We build Predictive AI model that analyzes real-time data streams from the production process and identifies potential outliers that may lead to quality deterioration based on process data.

Client

Challenges

Company from Poland, a producer of Active Pharmaceutical Ingredients, was struggling with the manufacturing efficiency of their current repeatable batch production processes. Over 50% of produced batches went to waste due to final product quality deterioration.

Solution &

Result

We identified critical regions that accounted for process alterations and applied anomaly detection using various deep learning techniques (RNNs, CNNs, and Transformers architectures).

Temporal patterns appear over windows of time in the gathered data. Our first step was to indicate which parts of the time series data hold insights that help discover unexpected behaviors, find early warning signs of possible quality deterioration, and create reliable alarms for the process operators.

A single data lake on historical batch quality records and in-process controls revealed hidden causes of quality deviations.

Predictive data analytics has been applied to track batches of products as they go through the entire manufacturing process. This allows for real-time adjustments when issues arise during the operation so that corrective actions taken will minimize disruption while maximizing efficiency.

The benefits are improved efficiency, predictability, and quality assurance of manufacturing operations and yields.

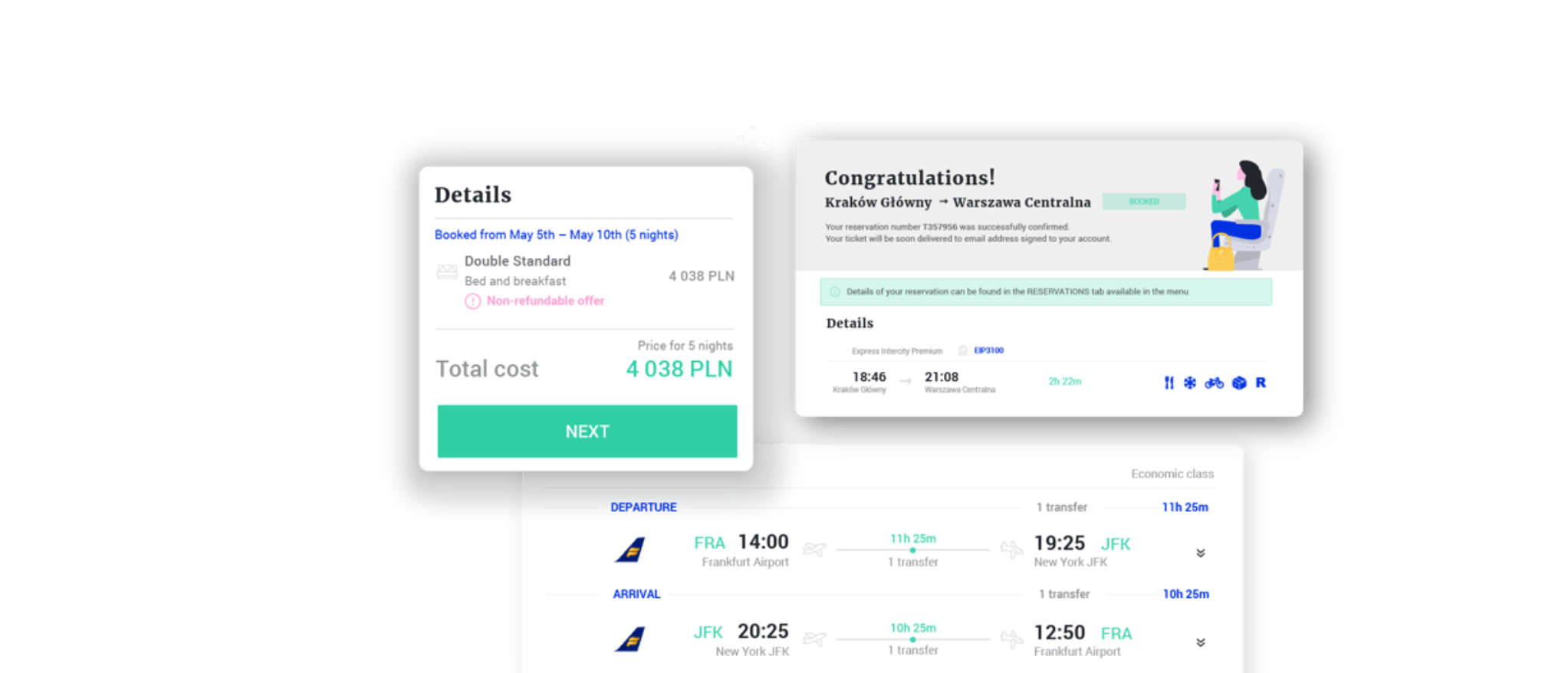

We delivered an B2B Travel Booking app that allowed easy searching and filtering of travel options, as well as recommendations based on previous bookings using Tensorflow Machine Learning Models