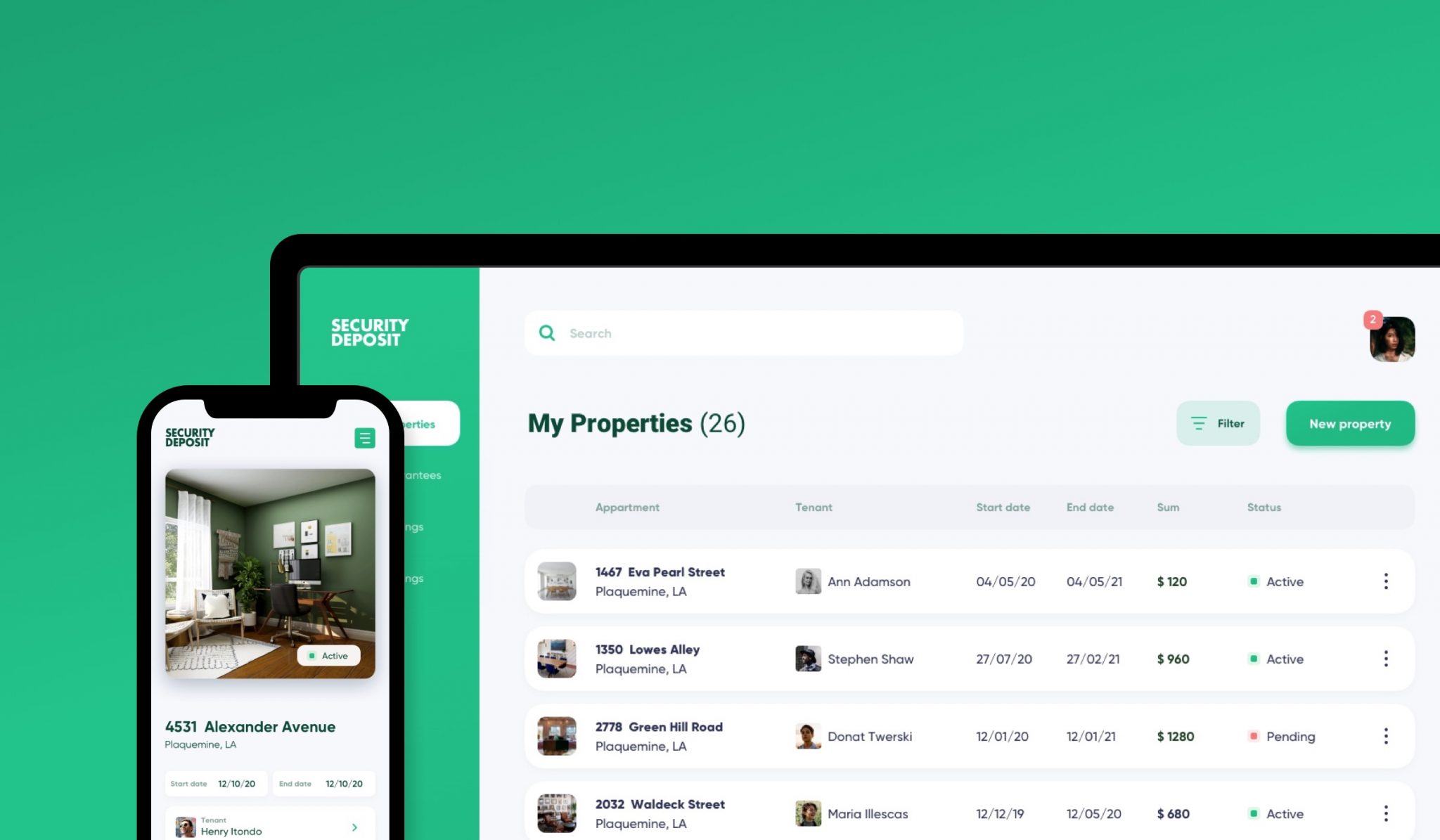

Our team helped an international fintech company to develop an innovative approach in B2C deposit guarantee operations for the European market.

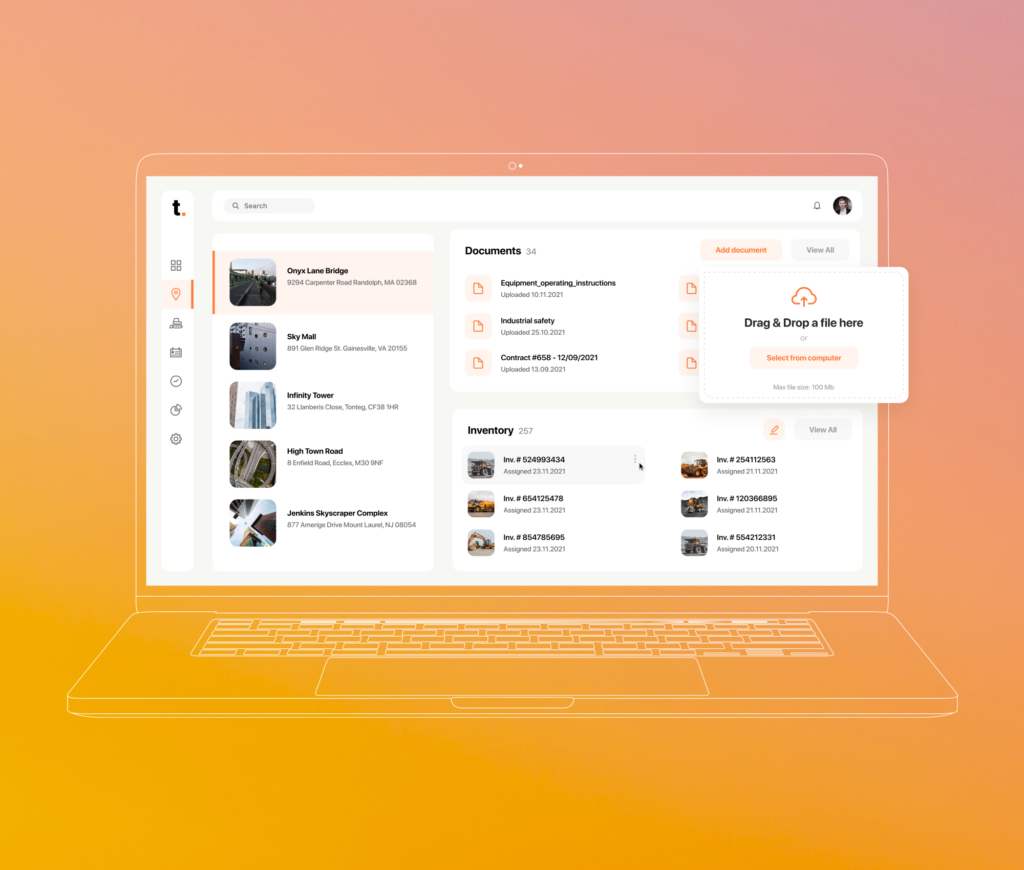

Construction Company ERP Web App

Client LOCATION

Frankfurt,

Germany

Tech Stack

Java Spring Framework, Docker, Gradle, Docker, Angular, AWS Cloud Services, MongoDB, Redis, Mockito

Team

2 Backend Developers 2 QA Engineers 1 Devops Engineers

Our Team has built ERP from scratch that provides workers with the most relevant information about materials and machinery. Our team has designed the solution in a way that allows workers in charge to update data in real time.

Client

Challenges

Our client has a wide range of materials and machinery geographically distributed over numerous warehouses and project sites. When planning a new project, it’s vital to operate the most up-to-date information about available resources. Also, due to several agreements with partners, some rented machines cost our client less when unused and this should be tracked and documented for further price cuts.

The client came up with the idea of a solution that would allow managers to plan new projects, logistics specialists to find the most efficient way of reassigning the resources, and other workers to track specific states of each resource for more efficient and cost-effective work.

Solution &

Result

The client’s machinery equipment as well as the equipment rented from partners has telematics sensors that track various conditions, from air pressure in tires to traversed mileage and fuel consumption.

Our team has designed a data-gathering module that automatically aggregates the data from such sources for further analysis and use. For instance, such information can show whether a particular machine consumes too much fuel and there’s a more efficient analog for replacement. Also, zero mileage over a certain period of time signals to lending partners that the machines have not been unused. Based on several agreements, our client pays fewer fees for unused vehicles on rent.

Another part of the solution is a GPS tracker. When a machine is assigned to a certain project, managers can set the location borders for it. When a worker moves this equipment across the established border, they get a set of notifications via the mobile app (push notifications) and emails. Also, the personnel responsible for the project and vehicle assignment get notified about such events.

All the collected data is aggregated at the back-end and assigned to a particular resource it’s related to creating a unique ID card. Through this ID card, employees and the client can gain access to the most valuable information in a prompt and conveniet way. The equipment ID card consists of a number of separate sections providing users with the specific information.

Description

This section provides general information about the item such as its inventory number, type, manufacturer, year of production, assigned warehouse or project, real-time location on the map, the total number of operating hours, personnel responsible for management or maintenance, etc.

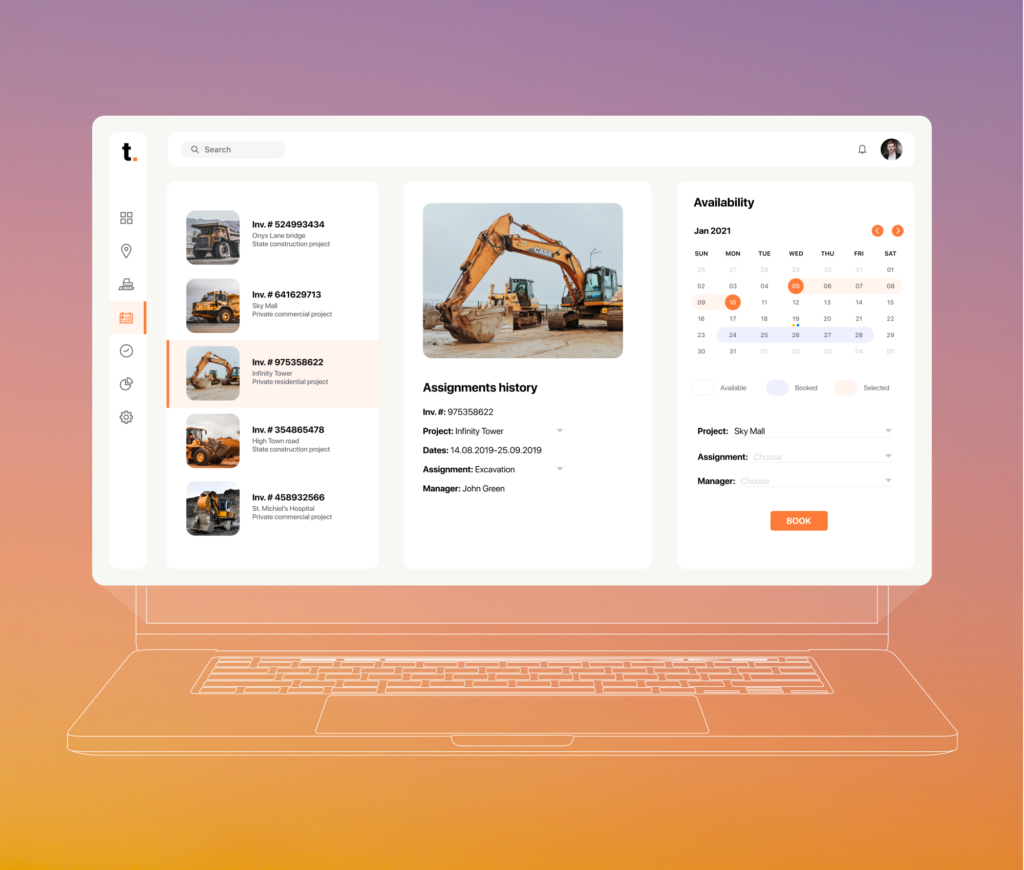

Assignments

This module allows project managers to check if the equipment is used at the moment and when it will become available, so they can reserve it for a necessary period of time. The history of assignments, responsible managers, and projects is stored in the system.

Statistics

This is a module representing a set of data about the equipment for a certain period, e.g. total number of operating and idle hours as well as their ratio, fuel consumption, state of the engine, etc. Information is visualized with diagrams and charts that make it easy to understand and compare.

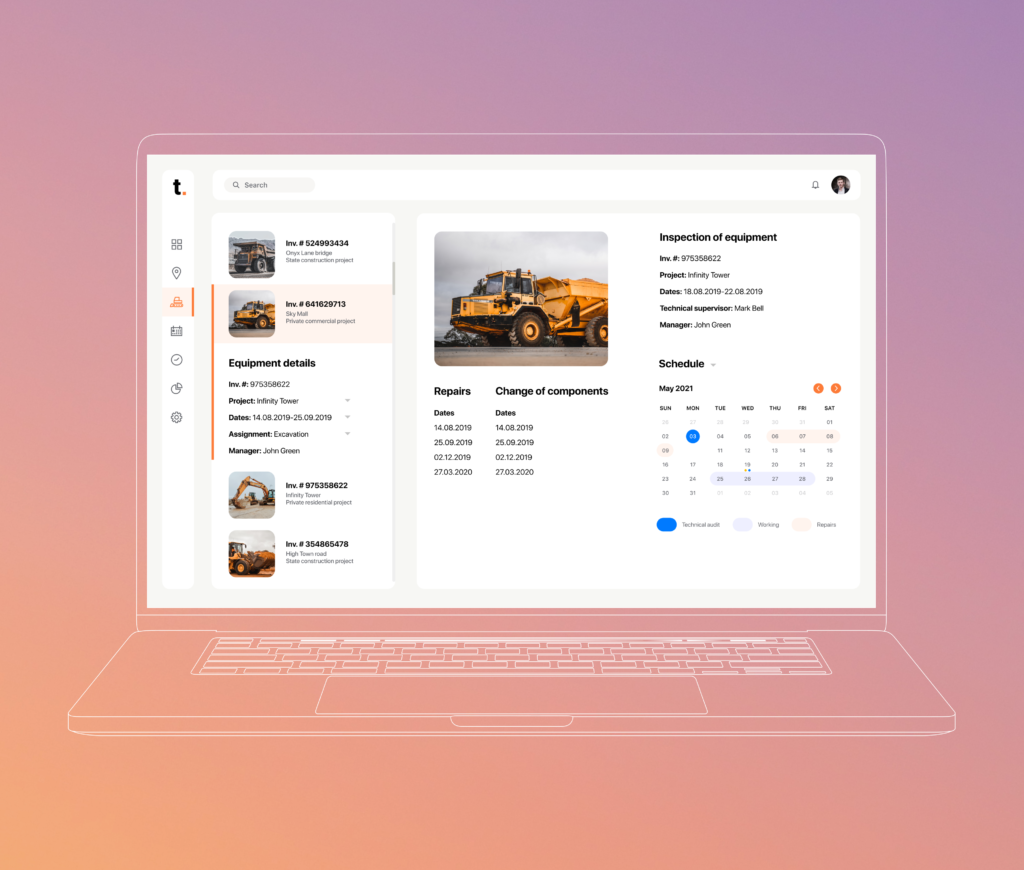

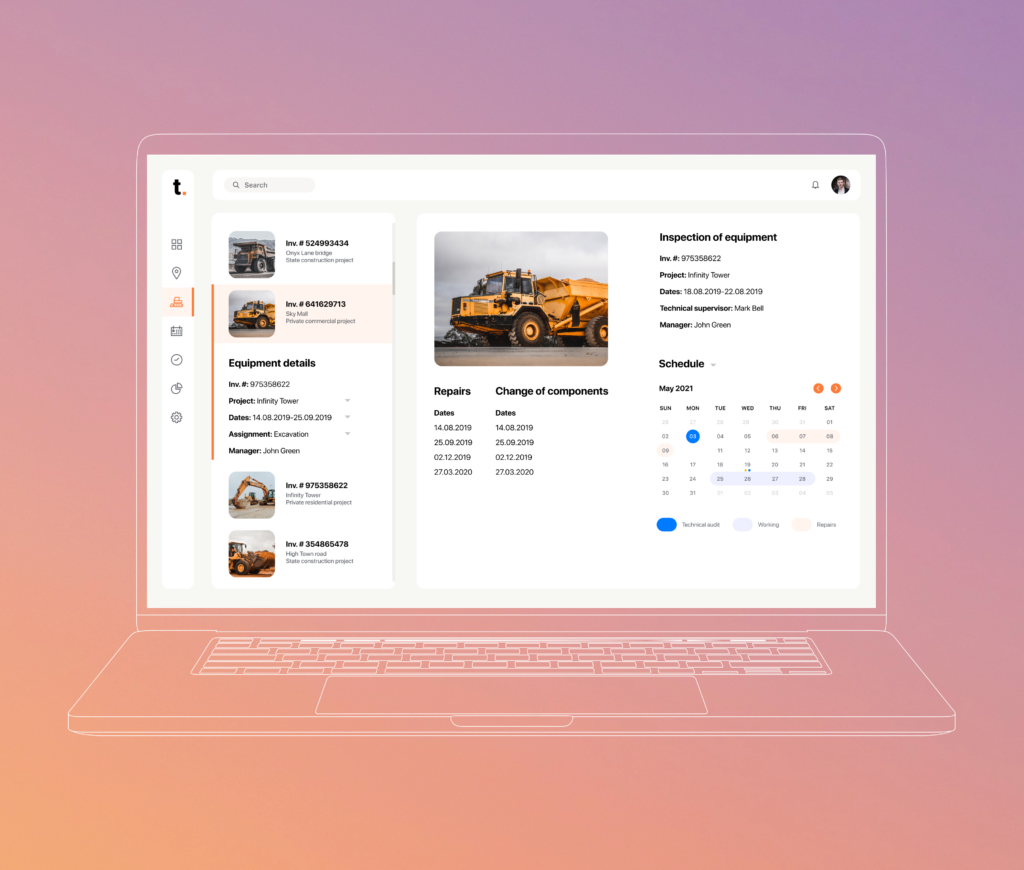

Maintenance

This section contains information about equipment inspections, repair works, changes of components, etc. Maintenance managers may set up notifications reminding them about the technical audit or oil change, and plan inspection processes in advance.

Costs

This module shows all expenses related to the equipment (fuel, components, maintenance, damage, etc.) that are accumulated in the system. A user needs to choose the type of performance, insert requested invoice details and attach an invoice, and the amount of money is charged to the correct cost center.

Interactive Map

This module gives access to an interactive map showing all the ongoing projects. By choosing one of them, a user can see assigned equipment and materials and when the equipment is presumed to be free of work. Such illustrative information helps users to manage the logistics of equipment between different projects more efficiently.

Project Management Board

The system has also a project management board in form of a Gantt chart where users can see a list of all available or disposed equipment, find a required one, and assign it for the project dates.

Reports

The reports section allows users to see general real-time statistics at a dashboard or generate custom reports by projects or periods of time.

Our Team helped the Dutch-based company expand the functionality and complete the development of an advanced dating application.

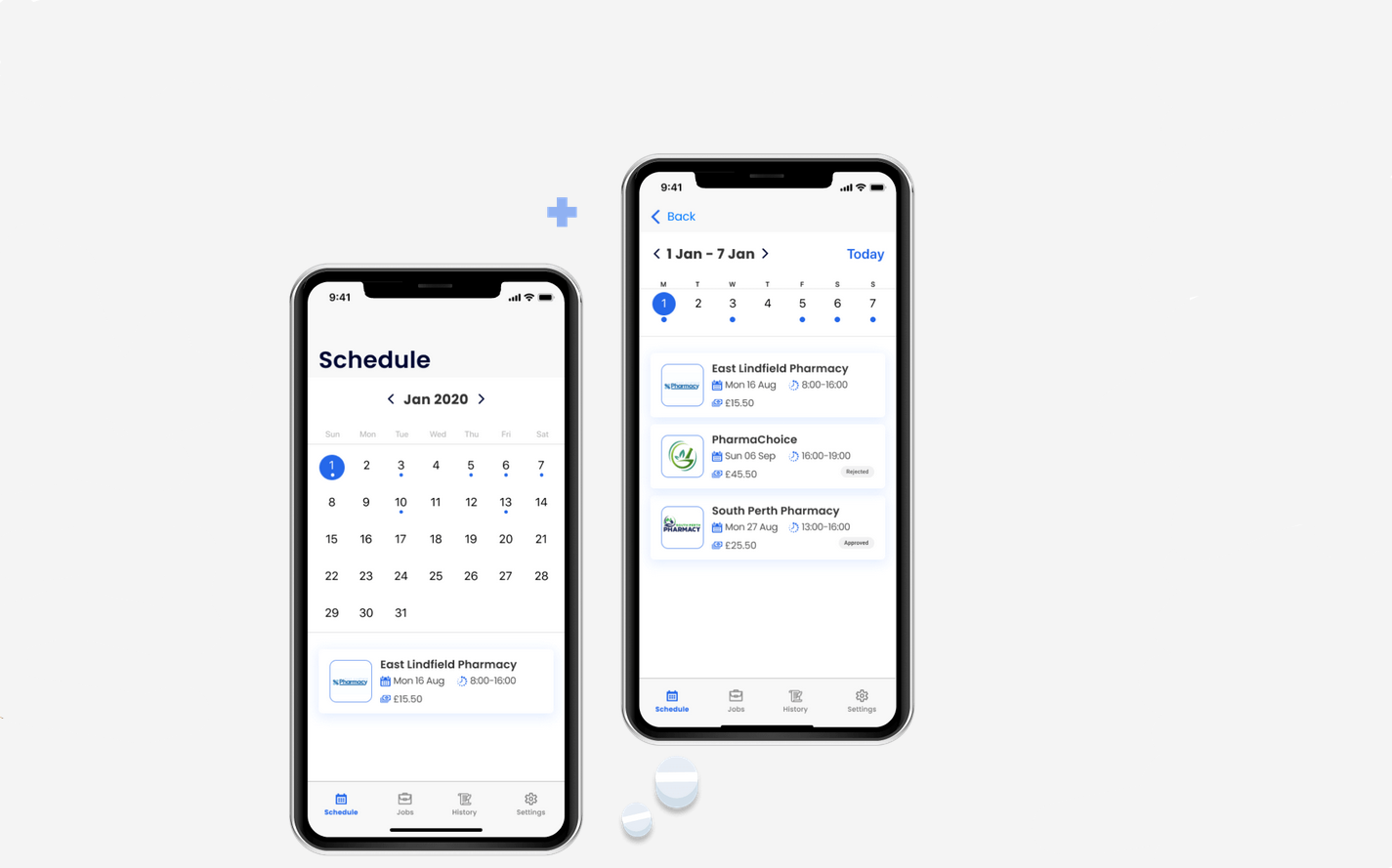

We built recruitment platform that streamlines and automates the recruiting process in the UK pharmaceutical market and overcomes a long-standing industry problem.

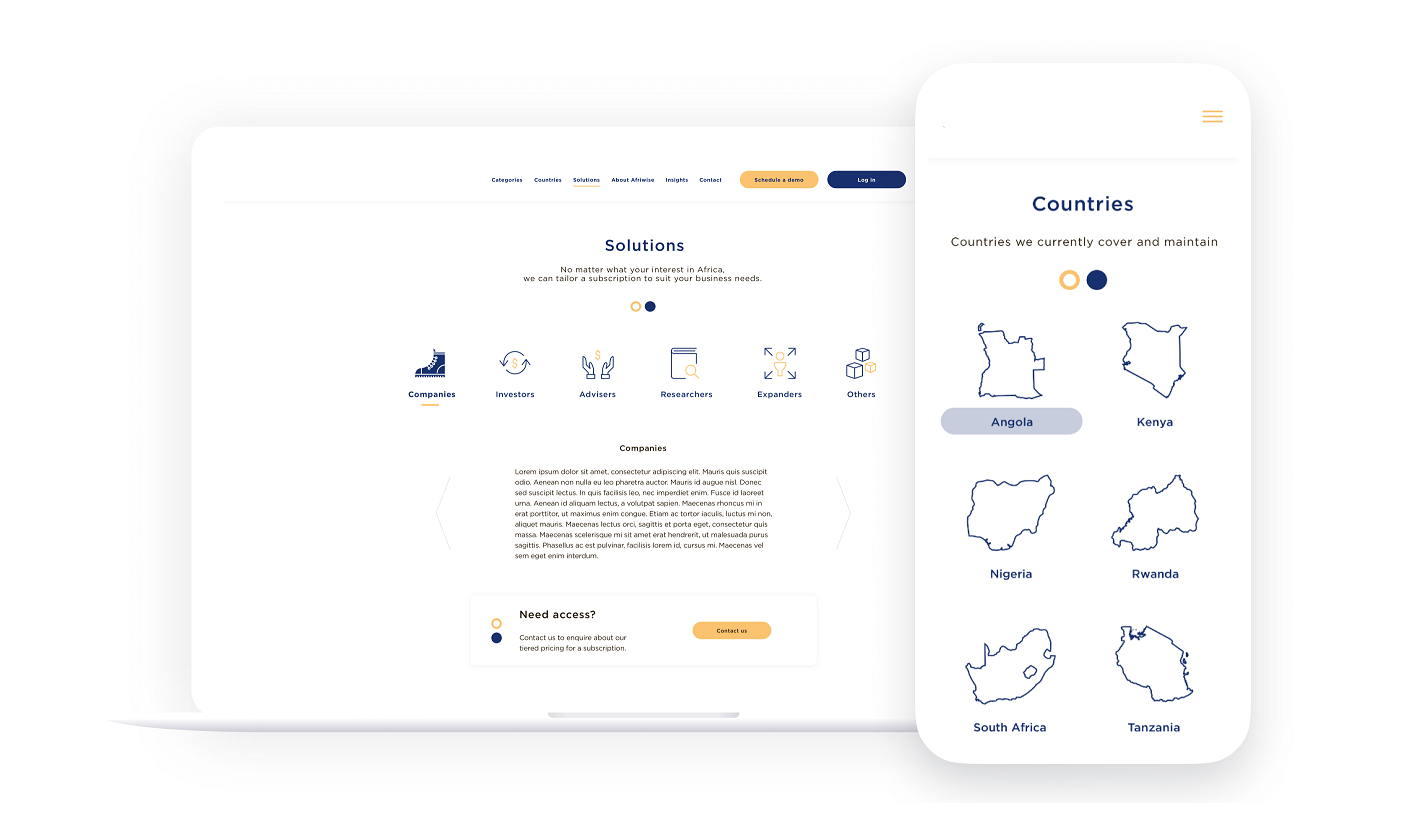

Our Team developed a web app for the Belgium based startup that act like legal bridge between Africa and Europe. It creates an easy door for companies to know the different regulations